The automotive industry is no longer just about horsepower, it’s about data power. Connected vehicle fleets, from delivery vans to long-haul trucks, generate a relentless stream of telemetry: GPS, OBD-II diagnostics, CAN bus signals, and more. This data is the key to smarter, safer, and more efficient operations. But harnessing it requires more than just technology; it demands a thoughtful approach to building systems that can handle complexity without breaking.

At SpiceFactory, we partner with automotive leaders to craft custom telemetry systems that turn raw data into real-world value. We believe in sharing the lessons we've learned from years of tackling fleet challenges. Here's a look at the art and science behind these systems.

Taming the Data Deluge

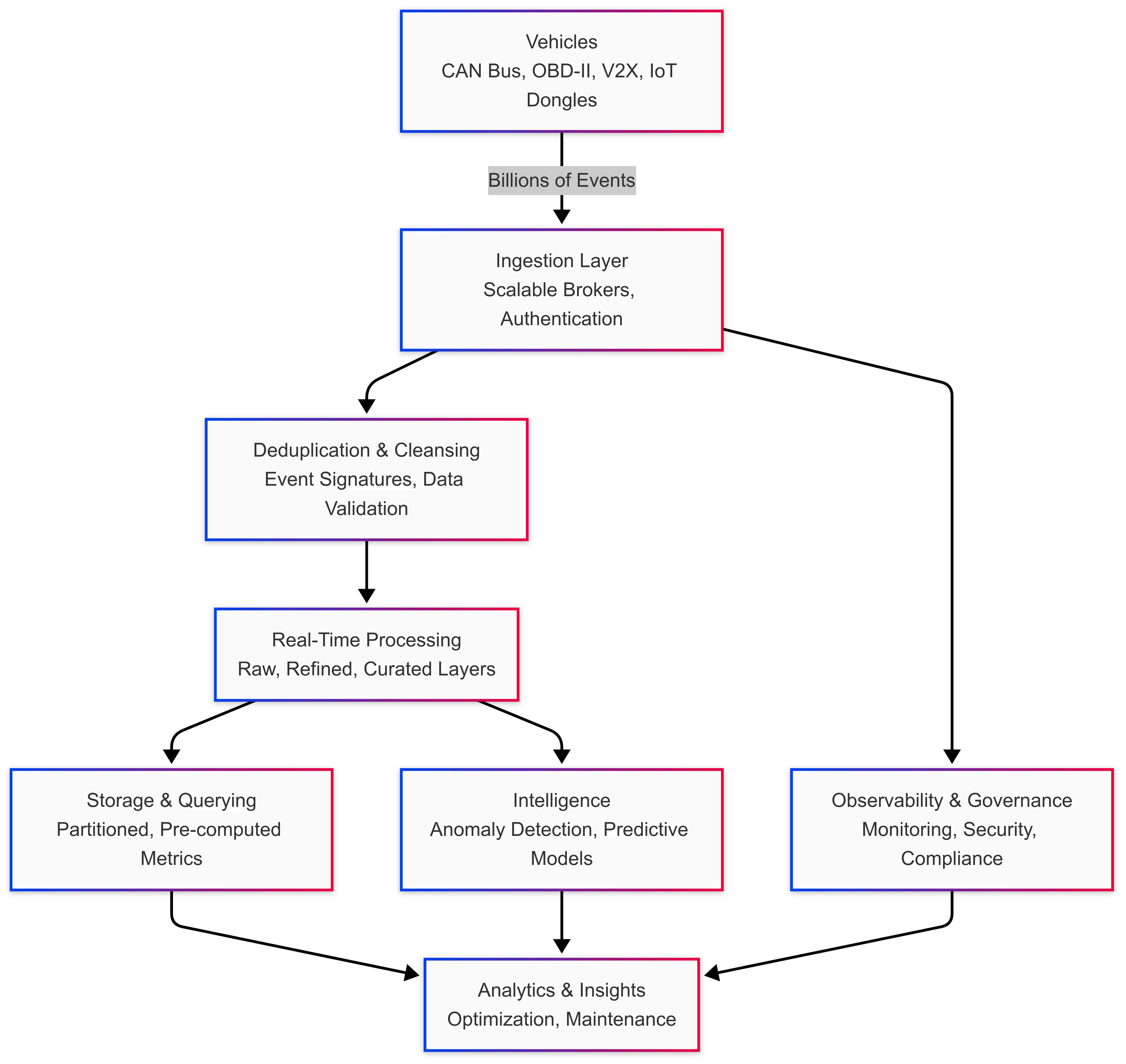

A single vehicle can generate hundreds of data points per second. Multiply that by thousands, and you're dealing with billions of events daily. For fleet operators, this deluge can overwhelm systems, leading to lost data or costly delays. The first challenge is building an ingestion layer that can keep up.

Success hinges on three core principles: scale, resilience, and security. Scalable systems use message brokers to handle sudden surges, like a fleet-wide alert during a storm. Resilience means caching data locally on vehicles to survive network drops. Security starts with authenticating every source, ensuring that OBD-II or V2X messages come from trusted devices.

A key insight: partition data by fleet or region from the start. One customer saw ingestion latency drop by 40% after we implemented regional partitioning, proving that smart design prevents bottlenecks before they begin.

Turning Noise into Clarity

Raw telemetry is messy: duplicate OBD-II packets, glitchy sensors, or GPS errors that place a truck in the wrong country. Unclean data leads to skewed analytics, misinformed decisions, and bloated costs. The solution? Cleanse and deduplicate early.

By using unique event signatures, we catch duplicates before they clog databases. Cleansing standardizes timestamps and filters out anomalies, like impossible battery readings. For one logistics client, early deduplication cut storage costs by 25%, freeing up budget for predictive analytics.

The lesson: cleaning data close to the source isn’t just about accuracy but also about efficiency. This ensures systems deliver reliable insights, whether for maintenance schedules or route optimization.

Delivering Insights When They Matter

Fleets operate in real time, and so must their telemetry systems. A delayed alert about a failing part can mean a stranded vehicle or a safety risk. Real-time processing turns raw data into immediate action.

We design systems with layered processing: a raw layer captures every event, a refined layer organizes it, and a curated layer delivers metrics like fuel use or part wear. This setup powers instant decisions, like rerouting a vehicle to a charging station before a battery fails.

A critical takeaway: speed trumps perfection. A 90% accurate alert delivered in seconds is far more valuable than a perfect one that arrives too late.

To illustrate, here’s how a typical telemetry pipeline flows:

Storing Data for Strategic Value

Real-time insights are critical, but long-term analytics drive strategic decisions. Storing billions of events like GPS traces, OBD-II diagnostics, or CAN bus data, without slowing down queries is a delicate balance.

Smart partitioning, like grouping data by vehicle or time, keeps queries fast. Pre-computed metrics, such as monthly fuel efficiency, save time for common analyses. We learned this the hard way when an early project suffered slow queries due to poor partitioning, requiring a costly overhaul. For one customer, optimized storage cut query times from minutes to seconds, enabling faster budgeting and fleet planning.

The insight: design storage with the end user’s needs in mind.

Anticipating Problems with AI

The best systems don’t just react, they predict. Embedding AI into telemetry systems can prevent issues before they escalate, saving time and money.

Anomaly detection models scan OBD-II data for issues like temperature spikes, flagging them instantly. Predictive models estimate part lifespans, scheduling maintenance before failures. A fleet operator we worked with saw a 15% reduction in breakdowns after implementing basic anomaly detection.

The lesson: start with simple, high-impact AI. Overcomplicating models early can delay value, so focus on what delivers results now.

Building Trust with Visibility and Security

A telemetry system is only as good as the trust it inspires. Without visibility into performance or robust security, even the best system will falter.

We monitor metrics like ingestion speed and error rates to catch issues early. Security is non-negotiable, encrypting data, controlling access, and complying with regional regulations. For one client, real-time system health monitoring during a fleet rollout built confidence, speeding up adoption.

The takeaway: transparency and security aren’t add-ons; they’re the foundation of a system fleet operators can rely on.

Takeaways

The opportunity is clear: telemetry is the strategic lever for making fleets safer, more efficient, and more profitable. At SpiceFactory, our expertise is forged in the trenches, turning these challenges into tangible business wins.

If you're ready to move from raw data to real impact, we’re here to build the solutions that will drive the future of connected fleets. Let’s talk!